HIGHLIGHTS

Cuba Block 9 PSC (Melbana 30% participating interest and Operator)

- Initial development of Unit 1B on track.

- All materials for Alameda-2 workover in country, workover on track for early February.

- Drilling rig to mobilise to Amistad-2 location immediately thereafter. - Melbana subsidiary approved as Operator in Cuba.

- Oil offtake contract terms being finalised with an international oil trader.

- Pre-bid seismic scouting process completed.

Corporate

- $9.7 million cash available at the end of the quarter.

Melbana Energy has announced the first phase of the development plan for Block 9, onshore Cuba. Melbana is Operator with a 30% interest.

Field development

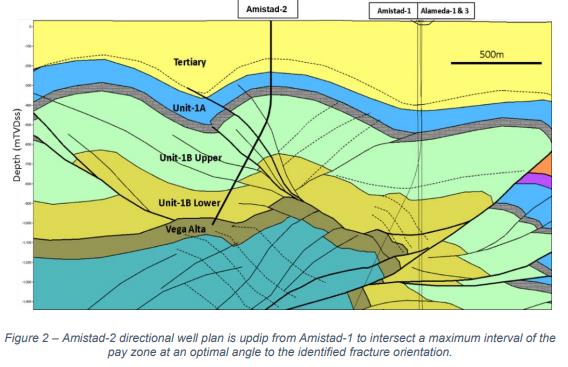

As announced at the AGM, the first phase of the field development plan will be a workover of the existing Alameda-2 completion within the Amistad Unit 1B reservoir followed by the drilling of a number of production wells into Unit 1B reservoir within the Amistad Structure, the first being the Amistad-2 well.

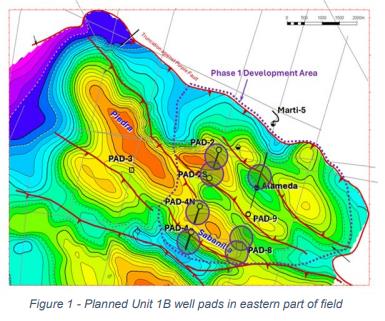

Using existing 2D seismic control, Amistad-2 will be drilled to the South from Pad #9 targeting the highest confidence (1C) resource of 16 million barrels(1) , in a location up-dip of Alameda-2.

Future 3D seismic will allow development wells to be accurately positioned to more efficiently develop and potentially extend the recoverable 2C Contingent Resource of 46 million barrels (1).

A pre-bid seismic scouting process was completed with contractors during the December quarter, data from which will be incorporated into the survey design.

The near-term goal to export a first cargo remains a priority.

Alameda-2 Workover

The workover of Alameda-2 is planned to commence in early February 2025. The program is designed to remediate interpreted near-well formation damage identified in the Amistad Unit-1B oil reservoir. The nature of this damage was determined by our in-house team and external experts analysing results from the original Drill Stem Test (DST) and subsequent Extended Production Testing. (2)

Key steps in the workover program include using a service rig to pull the completion, add perforation intervals in the upper and lower Unit 1B and undertake an acid wash and squeeze before re-running the completion.

Drilling additional well into Unit 1B

Preparations for the drilling of Amistad-2 are well advanced and an outline drilling program was compiled during the quarter. The drilling program incorporates all lessons learned to date in order to maximise the well’s flow potential. Amistad-2 is to be drilled from Pad #9 in a southerly direction, along the existing 2D seismic line, and is designed to intersect the entire Unit-1B pay interval and numerous interpreted fracture sets. The surface location is approximately 800m from and 200m updip to the successful Alameda-2 well.

Following the observation of formation damage during extended production testing of Alameda-2, and subsequent likely formation damage in Alameda-3, the Company decided to investigate alternate drilling fluid systems. Preliminary investigations led Melbana to develop a Reservoir Drilling Fluid (RDF) for the Alameda field.

The use of RDF is relatively common for formations susceptible to drilling induced damage. Melbana’s RDF is a water-based drilling fluid that is designed to minimise the risk of formation damage, whilst maintaining the ability to safely and effectively drill the well.

During the quarter, scanning electron microscope images of Alameda-3 core samples were received, providing direct indications of formation damage including barite embedment and crystalline precipitates within pores and fractures of core plugs. This information was incorporated into the extensive chemical analysis and final design of the RDF and associated fluid and rock compatibility testing, which confirms its suitability for the Unit-1B reservoir.

Given the dedicated Unit-1B target for Amistad-2, it has been possible to significantly simplify the well design. As such, it is expected that the well will be completed open-hole, with 7” slotted liner available as a contingency, an application which works well with the proposed RDF. The completion tubing will then be run before a pre-production acid-wash being circulated and the well then brought immediately into production without the need to kill the well.

Drilling is planned to commence immediately after the workover of Alameda-2.

Commercialisation

A significant component of Melbana’s commercialisation plans were realised when Melbana’s subsidiary was approved as an operator in Cuba. Melbana’s engineering and commercial teams continue to progress plans for the export of oil produced from Block 9. The preferred plan is to truck crude to receiving pits connected to oil storage tanks at the nearby oil storage terminal before export from the port. Crude exports are expected to continue to be pursued to underpin the Company’s long-term ambitions for the project. The Company continued its discussions with several potential new partners and credit providers who have demonstrated interest in participating in the development of Block 9.

Click here for full announcement

Source: Melbana Energy